What are the common types of packaging materials? Packaging materials occupy a very important position in the entire packaging industry, the basis for developing packaging technology, improving packaging quality, and reducing packaging costs. Therefore, to understand the performance, application scope and development trend of packaging materials is relatively related to the materials that packaging materials must have. This not only saves the time of purchasing and finding a manufacturer, but also provides greater discounts 3. Save more costs.

The materials in the packaging materials line can be divided into the following five categories

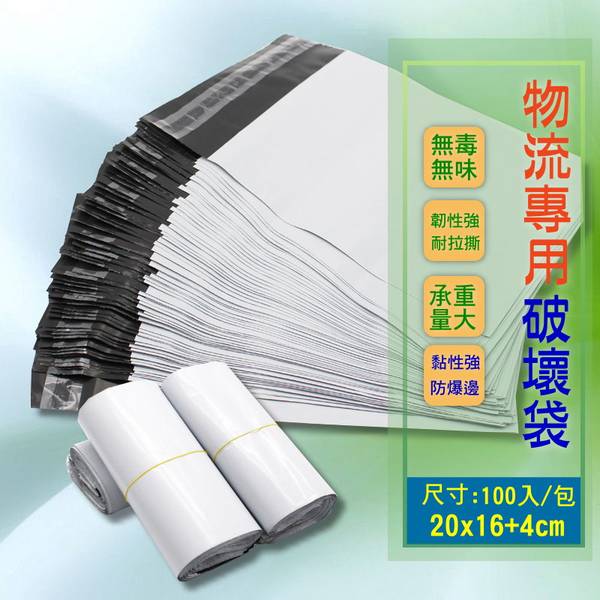

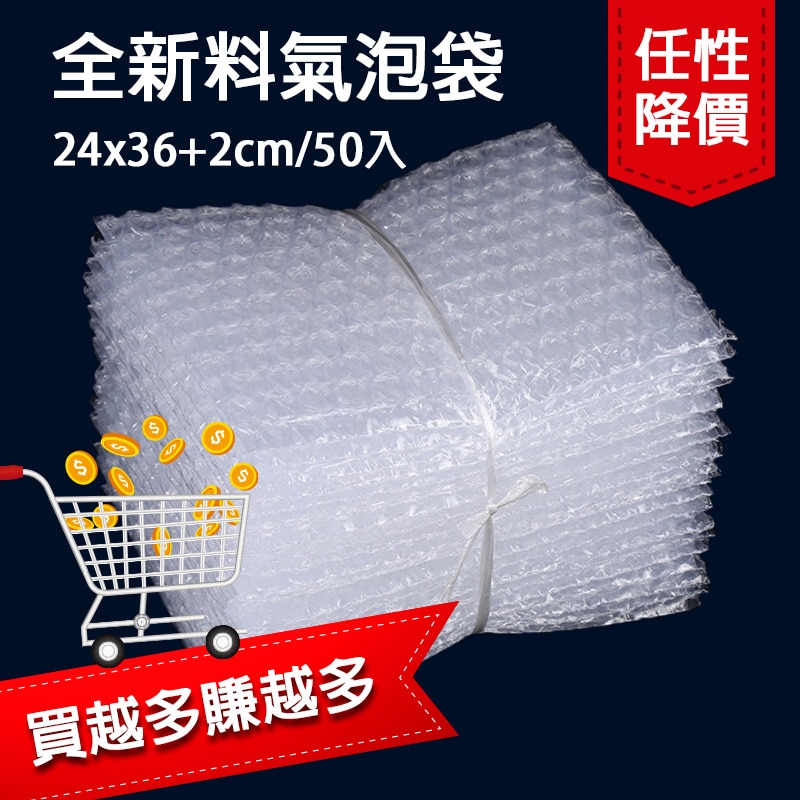

1. Classification of general packaging materials: destruction bags, bubble bags, Shumei cloth, tape, fruit net bags, etc.

The above packaging materials are very common and available in the packaging materials industry .

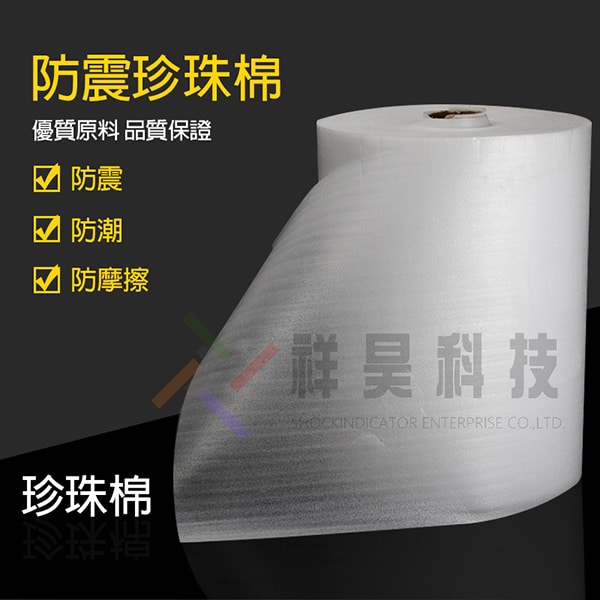

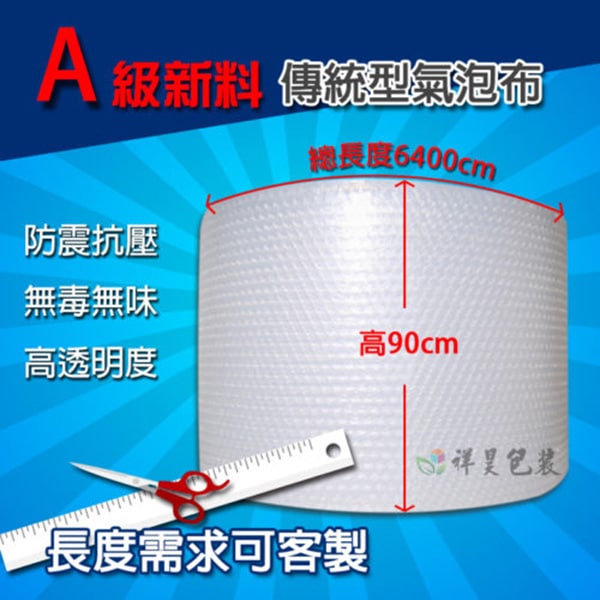

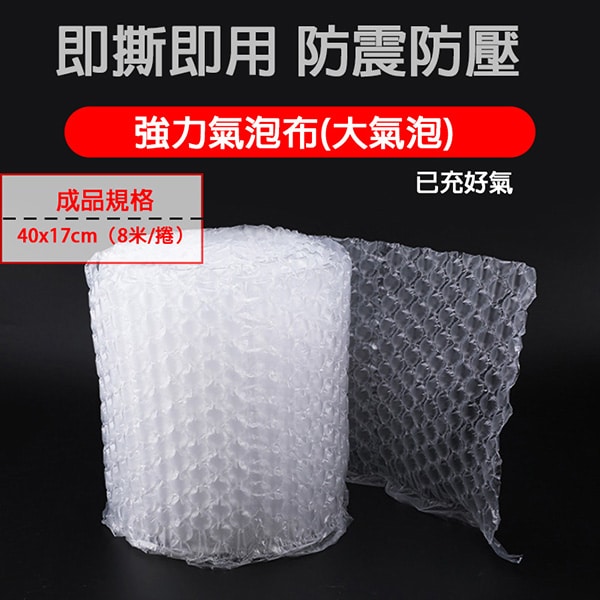

2. Classification of cushioning packaging materials : traditional bubble cloth, strong bubble cloth, air column bag, bag in bag, pearl cotton lining, etc …

Strong bubble cloth, air column bag and bag-in-bag are the newest cushioning air packaging materials in the new trend of 2020. They are not common in general packaging materials . You need to find it in a special packaging material line ~

Third, the classification of filled packaging materials: obedient granules, filled bags, AB foam bags, cushioned air cushion bags, shredded raffia, etc …

The most common filling and packaging (box packing voids) obediently grain, broken wire or raffia shredding general packaging materials can be purchased.

Filled bag, foam bags, these bags air cushion packaging materials are special packaging materials to buy into.

4. Classification of container packaging materials: pallet film, paper corner protector, container inflatable bag, fiber packing belt, packing tensioner, etc …

Pallet film can be purchased in general packaging materials, but paper corner protectors, container inflatable bags, fiber packaging tapes, and packaging tensioners need to be purchased in special packaging materials.

Fifth, the classification of food packaging materials: vacuum sealing and preservation machine, vacuum bag, chain bag, sealed bag, PET fruit box, etc …

The above packaging materials are very common in the packaging materials line and are also available for purchase.

The role of product packaging

1. Protection function: The protection function is the most basic element of packaging, so that the goods are not damaged by external pressure.

2. Convenience function: The so-called convenience function refers to whether the product packaging is easy to use, carry and store. The packaging materials used for a good product should stand from the consumer’s point of view, which can increase the consumer’s trust in the product and the desire to buy.

3. Sales function: As long as the quality of the product is good, there is no worry about selling it. In today’s increasingly fierce market competition, the role and importance of packaging materials also bring more extended development trends for packaging materials.

Why choose new cushioning packaging materials?

1. Benefits of cushioning packaging materials

Cushioning packaging refers to packaging designed to cushion shocks and vibrations and to ensure that its shape and function are intact. The general cushion packaging has a three-layer structure, that is, the inner layer of goods, the middle layer of cushioning material and the outer layer of the packaging box. The cushioning material can effectively absorb energy when external force acts, and disperse the force in time to protect the commodity.

Second, the advantages of cushioning packaging materials

1. The absorption of impact energy means that it has a good absorption effect on the impact of the commodity.

2. Cushioning packaging materials should be easy to process and form, easy to operate, and cheaper in price. Waste can be reused and burned, but it will not cause environmental pollution.

3. Suitable temperature and humidity buffer packaging materials can maintain its good buffer performance at low temperatures.

Third, the trend of cushioning packaging materials

With the increasing awareness of environmental protection, the requirements for environmental protection of packaging are becoming higher and higher. Relatively, the analysis and recognition of packaging have been further improved. In the future development of the packaging industry, people’s understanding of the packaging industry is no longer limited to the use of traditional packaging materials, but to use various advanced scientific technologies to create a variety of new packaging materials that meet the needs of the packaging industry. It is the basis and premise for the future development of the packaging industry.

https://youtu.be/Ss3SeixhNNI

If you have any questions, please contact us

- INE ID: @ whu6111z

- Customer Service Hotline: 02-26980080

- Please read the shopping instructions / after-sales service before placing an order

- Customer service time: Monday to Friday 9: 00-18: 00

- Sixth, Japan, national holidays (according to public holidays) leave.

- Shipping time: Monday to Friday at 14:00 (after the order is shipped the next day, it will be delayed during holidays)

- For e-commerce companies that need to purchase in large quantities, please contact customer service (◕‿◕✿)